Heat exchangers play a crucial role in a wide array of industrial processes, serving as essential devices that facilitate the movement of thermal energy between two or more liquids. Whether in manufacturing, energy production, or heating, ventilation, and air conditioning systems, these devices are critical for enhancing energy efficiency and ensuring optimal operations. Grasping how heat exchangers work and their various types can greatly enhance our appreciation of their significance in both industrial applications and daily life.

In this article, we will explore the various kinds of heat exchangers, explore their applications across multiple industries, and emphasize the necessity of regular maintenance to avoid performance issues. From the classic shell and tube designs to modern compact models, we will also cover factors to consider when choosing the right heat exchanger for your particular requirements. As we anticipate the future, it is crucial to recognize the continuous improvements in heat exchanger technology and how they contribute to sustainable practices in an increasingly energy-conscious world.

Categories and Applications of Thermal Exchangers

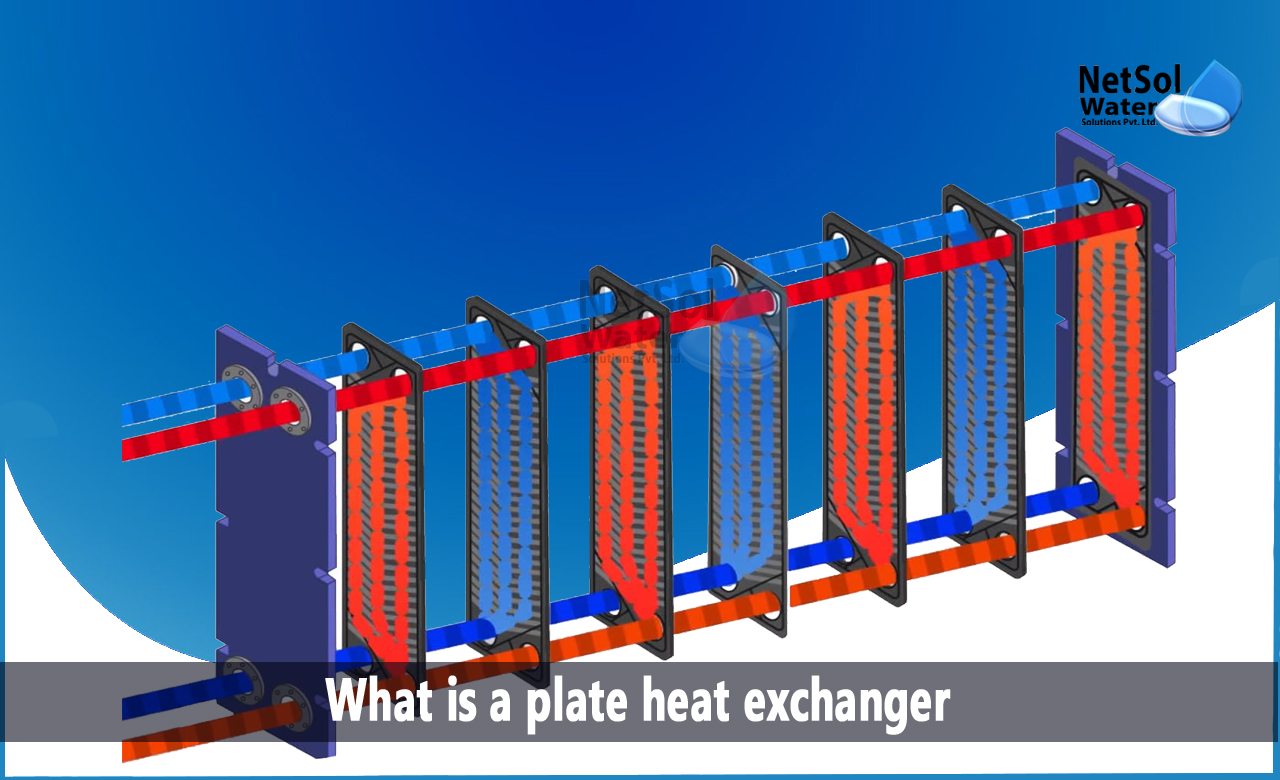

Thermal exchangers are essential components in a variety of commercial uses. The primary types of thermal exchangers include shell and tube heat exchangers, plate heat exchangers, and air-cooled heat exchangers. Shell and tube heat exchangers consist of a collection of tubes, one set carrying the heated fluid and the second the cool fluid, allowing for effective heat transfer between them. Plate exchangers, on the contrary, employ several flat plates to create channels through which liquids flow, providing a greater surface area for heat transfer in a concise design. Air-cooled heat exchangers utilize surrounding air to cool liquids, making them perfect for applications where water is scarce.

In the chemicals sector, heat exchangers are crucial for processes such as distillation, where they assist in the transfer of thermal energy to maintain suitable temperatures for chemical processes. Similarly, in energy facilities, thermal exchangers play a critical role in converting the heat generated from fuel combustion into power. Their applications extend to food and beverage processing, where maintaining specific temperature conditions is crucial for safety and quality.

The adaptability of thermal exchangers also makes them essential in heating, ventilation, and air conditioning systems, where they manage heat and ensure comfort in structures. In renewable energy systems, heat exchangers help collect and transfer energy from sources like solar energy and geothermal. As industries evolve, the development of tailored thermal exchangers tailored to meet unique requirements continues to broaden their applications across multiple sectors.

Efficiency in Energy Use and Upkeep

Thermal exchangers play a pivotal role in enhancing energy conservation across various industrial applications. By shifting heat between liquids, they minimize the need for further heating or chilling, which can notably reduce energy expenditure. In various instances, optimizing the heat transfer efficiency can lead to considerable savings and reduced environmental impact, making these machines crucial for companies dedicated to eco-friendliness.

Frequent servicing of thermal exchangers is necessary to ensure they operate at peak performance. Fouling, a typical challenge caused by the build-up of unwanted substances on heat transfer surfaces, can hinder performance and lead to higher energy consumption. Routine check-ups and servicing can avoid these reductions in performance and lengthen the duration of the infrastructure. Implementing digital monitoring systems can also aid in identifying performance degradation quickly, allowing for prompt service actions.

Moreover, selecting the suitable materials, such as durable metals for its corrosion resistance, can boost the durability and performance of heat exchangers. Understanding Learn here of each scenario will help in determining the ideal design and maintenance strategy. With the right strategy, companies can maximize energy savings, limit inactivity, and enhance the overall performance of their systems.

Breakthroughs and Future Trends

The heat exchanger industry is undergoing major innovations aimed at enhancing efficiency, productivity. Advanced materials such as polymer composites and new alloys are being investigated to improve heat transfer efficiency while reducing corrosion and fouling. Additionally, the integration of intelligent technologies, such as Internet of Things sensors, is transforming how heat exchangers are supervised and maintained, enabling operators to gather live data and enhance performance dynamically.

Another movement is the development of compact and modular heat exchangers, which are engineered to nestle in smaller spaces while maintaining high performance. These designs cater to industries where space is at a premium price, such as in electric vehicles and renewable energy systems. Advances in additive manufacturing (3D printing) are also opening the way for complex designs that can improve thermal performance and reduce material waste, making production more green.

Finally, eco-friendliness is becoming a central focus for heat exchanger innovation. The drive towards greener technologies is leading to the production of heat exchangers that enable energy recovery and reduce overall carbon footprints. As businesses and industries commit to diminishing energy use and emissions, the outlook of heat exchanger technology will likely emphasize eco-friendly operations, with an emphasis on sustainability practices and environmental impact of materials used in their manufacture.