Heat exchangers are essential components in a wide range of industries, playing a vital role in the regulation and transformation of heat. By facilitating optimal heat transfer between multiple fluids, they help optimize processes from power generation facilities to refrigeration systems. Comprehending how heat exchangers operate and their diverse implementations reveals their value in enhancing energy effectiveness and supporting sustainability, making them essential for modern engineering and environmental stewardship.

As we delve into the principles behind heat exchangers, we will explore the various types available, such as tube and shell and plate heat exchangers, and highlight key differences that affect their application. We'll also examine their important role in heating, ventilation, and air conditioning systems, the power industry, and the food industry, in addition to developments shaping their future. By acknowledging the sophistication and capabilities of these units, we can begin to see how they convert heat and contribute to economic benefits and efficiency improvements across numerous fields.

Grasping Thermal Exchange Systems

Heat exchangers are essential components in numerous mechanical systems employed to convey thermal energy between two or more fluids. They operate on the principle of heat transfer, where one fluid gives off heat while another absorbs it, allowing for energy effectiveness in processes such as heating, chilling, and energy reclamation. This process can occur in a variety of configurations, typically involving separated fluids to prevent mixing, which guarantees that the heat exchange takes place efficiently without interference.

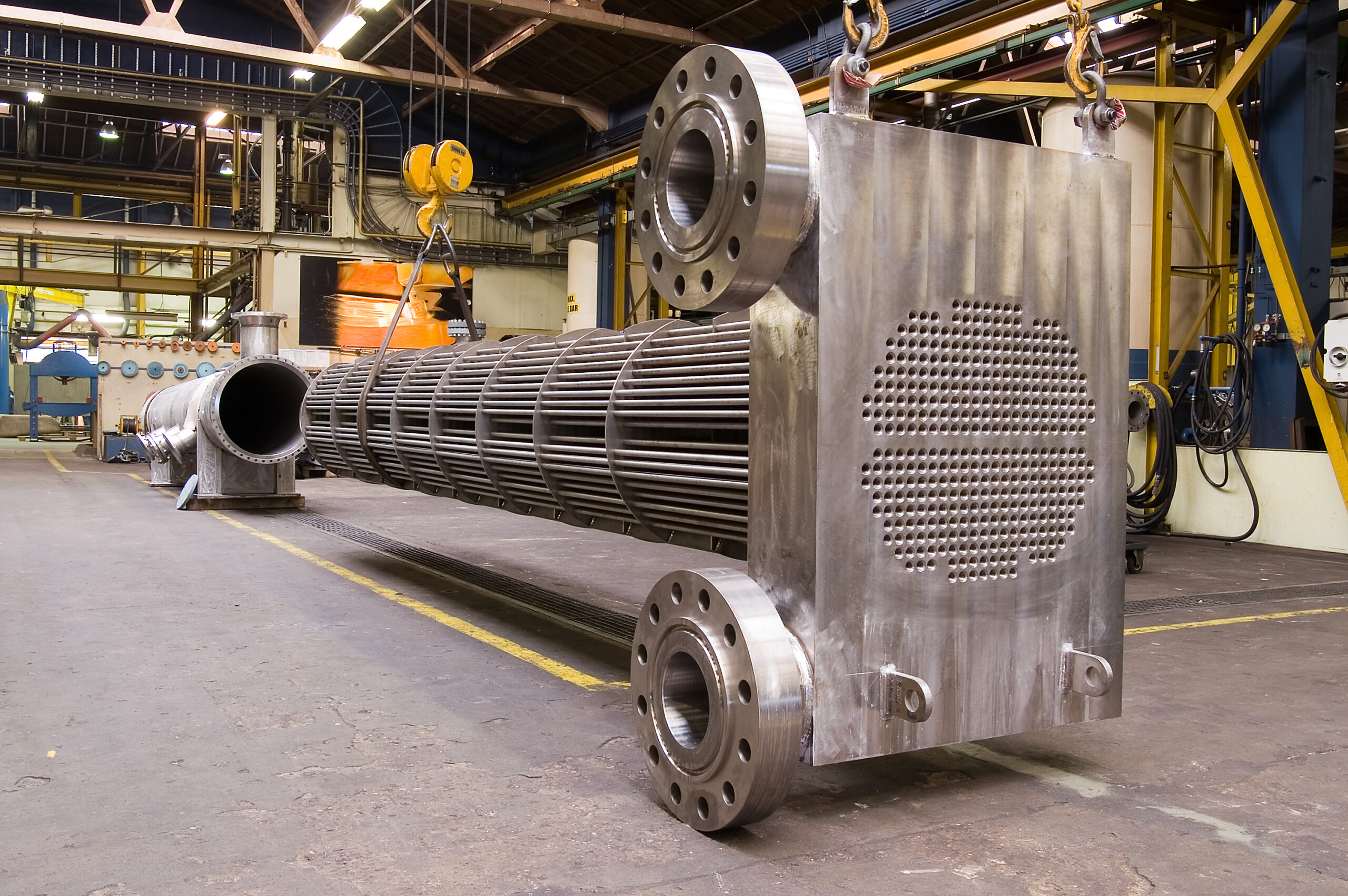

There are several different types of heat exchangers, including tube and shell, plated, and air-cooled arrangements. Each type performs specific applications and comes with its own range of advantages and disadvantages. Grasping these differences is crucial for selecting the appropriate heat exchanger for a specific application. For instance, shell and tube heat exchangers are commonly employed in large industrial settings due to their sturdy design, while plate heat exchangers are admired for their compactness in smaller installations.

The role of heat exchangers extends past simple thermal management; they are crucial in boosting overall energy efficiency. By capturing and reusing waste heat, heat exchangers support decreased energy consumption and reduced operational costs across multiple industries, including HVAC, power generation, and food processing. This interaction between energy conversion and resource protection is increasingly essential as industries strive for sustainability and reducing their carbon footprint.

Heat Exchanger Uses

Thermal exchangers play a crucial role in a diverse industries by facilitating the exchange of heat between multiple fluids. In the heating, ventilation, and air conditioning sector, they are essential for providing heating and cool in domestic and commercial buildings. By effectively transferring https://standardxchange.com/ , these systems help maintain ideal indoor climates, improving occupant comfort while lowering energy consumption. This performance is key for achieving energy savings and minimizing eco-footprint in current architecture.

In the electricity generation industry, thermal exchangers are fundamental to the operation of electric plants, including both conventional and nuclear facilities. They help manage the heat produced during energy generation, facilitating for effective heat recovery and improved overall efficiency. The use of thermal exchangers here not only enhances energy output but also plays a critical role in meeting environmental regulations by reducing emissions and waste heat.

Another important application is found in the food and beverage industry, where heat exchangers are employed for pasteurization, sanitation, and cooling processes. In this setting, they ensure the safety and quality of food products while maintaining energy efficiency. Moreover, their role in green energy solutions, such as solar thermal applications, further emphasizes their adaptability and value in modern energy solutions, providing eco-friendly options for reducing reliance on fossil fuels.

Maintenance and Efficiency

Appropriate maintenance is essential for preserving the efficiency of heat exchangers. Regular inspections and tidying up help prevent fouling, which can considerably impact heat transfer efficiency. By routinely checking for indications of corrosion, leaks, or blockages, operators can confirm that the heat exchanger operates at maximum performance levels. Scheduled maintenance not only extends the lifespan of the system but also avoids costly downtime and repairs in the future.

To improve energy efficiency, it is crucial to track the performance of heat exchangers continuously. Using digital monitoring systems allows for real-time data gathering on temperature differences, flow rates, and pressure drops. This data enables quick identification of potential issues, ensuring that any anomalies are resolved quickly. By maximizing the operational efficiency of heat exchangers, industries can achieve substantial energy savings and reduce total operating costs.

Committing in proper maintenance and monitoring practices corresponds with sustainability goals as well. Effective heat exchangers consume less energy, leading in lower greenhouse gas emissions. By focusing on maintenance, organizations not only enhance their machinery but also contribute to a further sustainable and environmentally friendly operation. With advancements in technology, the future of heat exchange systems will increasingly focus on integrating efficient designs and maintenance strategies that promote both performance and environmental responsibility.